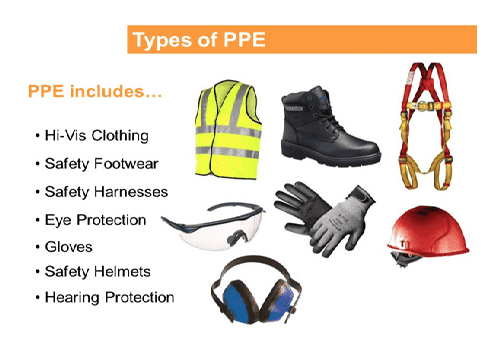

Personal Protective Equipment -- PPE

Personal protective equipment or PPE is important for every construction worker.

Every worker on the job site should have and use the appropriate PPE. It minimizes exposure to a variety of hazards while working on the job site such as protecting against sharp edges, falling objects, flying sparks and chemical splashes.

PPE that is typically used on construction job sites include your hard hat, safety glasses and face shield, gloves, work boots, earplugs and muffs and respirators.

Hard hats protect you from falling or flying objects and some rated to protect against accidental head contact with electrical hazards. You should put it on from the moment you set foot on the job site until the time you walk off. And make sure you check the hats ratings to ensure it's the right hard hat for the tasks at hand. It should be worn with the visor, the bill, the front according to manufacturer's specifications. Hard hats are made up of 2 basic parts, the shell and the suspension. The shell protects you from the impact while the suspension serves as a shock absorber. And both are necessary to provide full protection. Hard hats must meet ANSI standard Z89.1. The suspension has a headband that's adjustable for a comfortable fit. Adjust your hard hat using the clip or the ratchet. Keep your hard hat in good condition. Don’t drill it, paint it or try to clean it with solvents. Routinely inspect your hard hat to make sure it is in good condition. Check for dents, cracks or deterioration. The hard hat suspensions needs to be replaced yearly per most manufacturers and the shell replaced every 5 years if it never fails an inspection. Harsh chemicals and extreme temperatures can make a hard hat degrade more quickly and must be replaced more frequently. If the hard hat has taken a blow or electrical shock, it must be replaced immediately.

Being able to see workers is important for safety. This is especially true for workers working around vehicles or mobile equipment. In an effort to prevent accidents from struck by hazards. Workers should wear high visibility garments that help alert vehicle operators of their presence, especially in low light environments. It's a good rule of thumb to wear a high visibility safety vest at all times when on the job site no matter what the task.

Eye protection and face protection should be chosen based on what tasks are being performed and hazards encountered such as impact from flying objects, chemical splashes, harmful dust or radiation from welding. You must wear impact resistant safety glasses anytime you could be exposed to flying material even if you're not working directly with that material. All eye and face protection must meet ANSI standard Z87.1. Goggles should shield the eyes again flying fragments, paint or chemical splashes and spray particles. Keep in mind that some goggles aren’t made to take impact.

Face shields protect the entire face against exposure to impact hazards, flying objects, wood chips and chemical splashes. Always check the shield impact radius to make sure it can withstand impact hazards.

Feet injuries like nail punctures, twisted ankles, crash injuries are common in construction. PPE. for your feet can lessen or sometimes prevent these injuries. On the construction site, you should wear shoes or boots with slip resistant and puncture resistant soles. And safety told or steel toed footwear to protect toes from falling objects and crushing injuries. Safety footwear must meet ANSI Z41 or ASTM standards. Tennis shoes are not acceptable footwear on the job site.

In construction you may also be exposed to many tasks that require hand protection from sharp or rough objects, chemicals, electricity and flames. Wear the right gloves for the task at hand and make sure they fit properly. The most common gloves worn on the job site include knit gloves, with a rubber palm to provide basic protection for minor cuts or abrasions. Chemical resistant gloves when working with wet concrete, mortar, adhesives or solvents. Welding gloves made of leather for use around heat and flame. And rubber insulating gloves and sleeves when exposed to electrical hazards.

Some jobs in the work site are allowed and may require hearing protection to reduce the amount of noise that gets through and lessen the risk of long-term hearing loss. You should use earplugs or earmuffs when using tools like drills, powder-actuated tools, pneumatic nailers, grinders and other heavy loud equipment. The noise reduction rating (NRR) is used to determine the effectiveness of hearing protection, the higher the noise reduction rating, the more reduction in sound exposure. When using earplugs, always make sure to follow the manufacturers’ directions on how to properly wear them.

On the job site there are some common materials like paints, lacquers, insulations, sealants and dust that could harm you if inhaled. This is one of the most common waste chemicals can enter the body. When used respirators can remove contaminants from the air. The most important steps in using any kind of respirator is to ensure a proper fit to protect yourself from harmful dusts, mists, gases, vapors and sprays getting into your respiratory system.

Using the right PPE is one of the most important safety tips to prevent serious injuries when working on the job site.

So be smart and be safe.