Everything You Need to Know About Welding Gloves

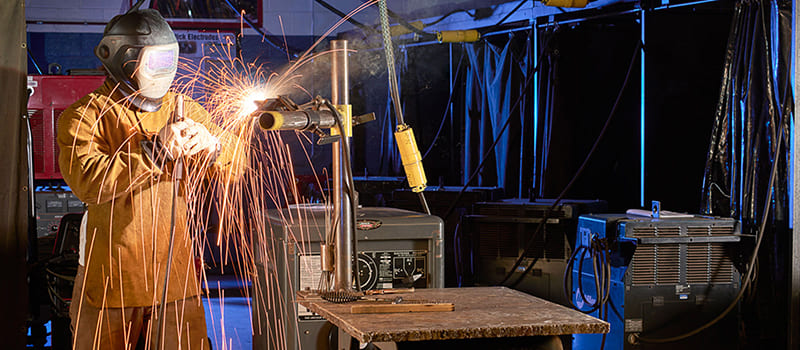

When it comes to welding, safety should be the top priority. One crucial aspect of welding safety is the use of appropriate personal protective equipment (PPE), including welding gloves. Welding gloves are specially designed to protect your hands from the intense heat, sparks, and potential hazards associated with welding processes. In this article, we will explore everything you need to know about welding gloves.

1、Material:

Welding gloves are typically made from a combination of durable and heat-resistant materials such as leather, Kevlar, and other flame-resistant fabrics. Leather gloves are commonly used due to their excellent heat and abrasion resistance. Kevlar provides additional protection against cuts and punctures. Some gloves also feature heat-resistant inner linings for enhanced comfort and insulation.

2、Heat Resistance:

Welding generates extreme temperatures, and your gloves must be able to withstand the heat. Look for gloves with heat resistance ratings that meet industry standards. The gloves should have a high melting point and excellent flame resistance to ensure they do not catch fire or melt under the intense heat.

3、Durability:

Welding can be a demanding process, and your gloves should be able to withstand constant wear and tear. Leather gloves are known for their durability and long lifespan. Double stitching and reinforced palm areas are common features that enhance the durability of welding gloves.

4、Fit and Dexterity:

While protection is crucial, it's also essential to maintain good dexterity and control while wearing welding gloves. Ill-fitting gloves can affect your ability to perform intricate tasks and handle welding equipment effectively. Look for gloves that offer a snug fit without compromising comfort. Some gloves are designed with pre-curved fingers to improve flexibility and dexterity.

5、Length:

Welding gloves come in various lengths, ranging from short cuff gloves to long gauntlet-style gloves. The length you choose depends on the specific welding application. Longer gloves offer better forearm protection against sparks and heat, while shorter gloves provide more flexibility and are suitable for light-duty welding tasks.

6、Additional Features:

Some welding gloves come with additional features to enhance their functionality. These features may include extra padding on the back of the hand for impact protection, reinforced thumb and palm areas for better grip, and extended cuffs with adjustable closures for a secure fit. Consider your specific needs and the type of welding you'll be performing to determine which additional features are necessary.

7、Care and Maintenance:

Proper care and maintenance can extend the lifespan of your welding gloves. Follow the manufacturer's instructions for cleaning and storage. Regularly inspect your gloves for any signs of damage or wear and replace them if necessary. Remember that worn-out gloves may not provide adequate protection.

In conclusion, welding gloves are an essential component of welding safety gear. Choosing the right pair of gloves can significantly reduce the risk of burns, cuts, and other injuries associated with welding. Consider the materials, heat resistance, durability, fit and dexterity, length, and additional features when selecting welding gloves. By investing in high-quality gloves and properly maintaining them, you can ensure a safer welding experience. Always prioritize safety and protect your hands with the appropriate welding gloves for each job.